Transform Your Engineering Timeline with Advanced 3D Scanning

Did you know that engineering teams implementing 3D scanning technology report average project time savings of 60% and error reduction rates exceeding 80%? In today’s competitive landscape, where compressed development cycles and first-to-market advantages can determine project success, the ability to rapidly capture, analyze, and utilize precise physical data has become a critical competitive advantage.

If your engineering projects are still relying exclusively on manual measurements, traditional documentation methods, or even older digitization technologies, you’re likely experiencing unnecessary delays, accuracy issues, and missed opportunities for parallel workflows that modern 3D scanning enables.

Our engineering specialists have implemented time-saving scanning solutions for hundreds of projects across industries, and today we’re sharing the proven strategies that can transform your project timelines while simultaneously improving quality outcomes.

Understanding the Time-Saving Mechanisms

Before exploring specific applications, let’s examine how 3D scanning fundamentally changes engineering workflows to save time.

Compression of Data Acquisition

Traditional measurement approaches capture data sequentially, point by point:

- Manual measurement: Recording individual dimensions one at a time

- Coordinate measuring machines (CMMs): Capturing points sequentially through physical contact

- Photographic documentation: Limited to visual reference without dimensional data

3D scanning transforms this process through comprehensive, rapid data capture:

- Complete geometry acquisition in a single session

- Millions of measurement points captured simultaneously

- Full surface documentation rather than sample points

- Integrated color and texture data when relevant

According to the National Institute of Standards and Technology, modern 3D scanning can reduce data acquisition time by 75-90% compared to traditional measurement methods while capturing exponentially more information.

Enabling Parallel Workflows

Perhaps the most significant time-saving aspect of 3D scanning comes from workflow transformation:

- Simultaneous team access to complete digital data

- Parallel processing of different project aspects

- Location independence through digital collaboration

- Immediate feedback loops for design and verification

“The ability to have multiple teams working simultaneously with the same dataset transforms project timelines,” explains our product design specialist. “What was once a strictly linear process becomes a concurrent engineering approach.”

The American Society of Mechanical Engineers has documented that parallel workflows enabled by comprehensive 3D scanning can reduce overall project schedules by 30-50% compared to traditional sequential approaches.

Time-Saving Applications Across the Engineering Lifecycle

3D scanning delivers time advantages throughout the engineering process, from concept through production.

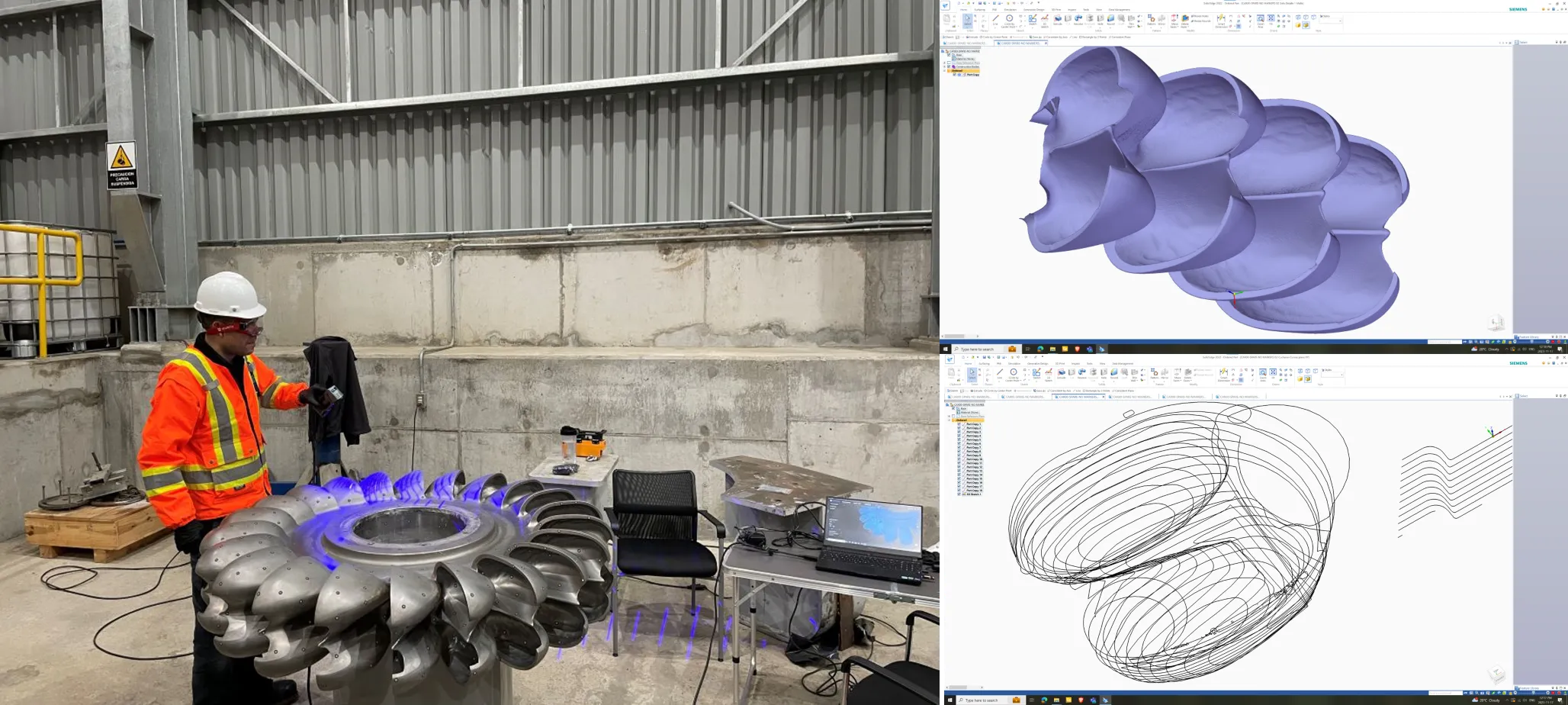

Accelerated Reverse Engineering

For projects involving existing components or competitive analysis:

- Complete part digitization in minutes instead of days

- Automatic feature recognition of common geometric elements

- Direct CAD conversion through specialized software

- Simultaneous 2D drawing generation from 3D scan data

“Reverse engineering that once took weeks can now be completed in days or even hours,” notes our reverse engineering team. “The comprehensive nature of scan data eliminates the iterative measuring and modeling cycle that consumes so much time in traditional approaches.”

A study by the IEEE Engineering in Medicine and Biology Society found that 3D scanning reduced reverse engineering time for medical components by an average of 73% while improving dimensional accuracy by 47% compared to manual techniques.

Streamlined Design Validation

For verifying physical prototypes against design intent:

- Comprehensive deviation analysis identifying all variations simultaneously

- Color-mapped visualization of differences for intuitive interpretation

- Automated reporting of out-of-tolerance conditions

- Digital record creation for documentation and collaboration

“Design validation that once required days of careful measurement can now be completed in hours with greater comprehensiveness,” explains our quality control engineer. “The ability to instantly visualize where and how a physical part differs from its design model transforms the iteration process.”

Our clients report an average 65% reduction in design validation cycles after implementing 3D scanning workflows, with some complex components showing time savings exceeding 80%.

Rapid Iteration Cycles

For design refinement and prototype evolution:

- Quick capture of physical modifications for digital integration

- Immediate feedback on design changes

- Hybrid modeling combining scan data with parametric design

- Digital-physical-digital cycles with minimal time loss

According to the Association for Computing Machinery, design teams using 3D scanning for iteration management typically achieve 40-60% more iteration cycles within the same development timeline, leading to more refined final products.

Efficient Quality Control

For production monitoring and verification:

- First article inspection in hours instead of days

- 100% part inspection rather than statistical sampling

- Automated comparison against CAD models

- Digital quality documentation generated automatically

“The traditional quality control bottleneck is largely eliminated through scanning automation,” notes our 3D scanning specialist. “A process that might have required days of careful CMM programming and measurement can be completed in hours with greater coverage.”

The American Society for Quality has documented that automated 3D scan-based inspection can reduce quality control time by 50-70% while simultaneously increasing inspection coverage from traditional sampling methods to 100% verification.

Industry-Specific Time Savings

Different engineering disciplines experience unique benefits from 3D scanning implementation.

Aerospace Engineering Efficiency

The aerospace industry faces extraordinary precision requirements and complex geometries:

- Tooling verification before expensive production runs

- Complex composite part inspection with comprehensive coverage

- Foreign object debris (FOD) identification through comparative scanning

- Critical component documentation for certification requirements

“Our aerospace clients have reported 60-80% reductions in tooling verification time after implementing structured light scanning,” shares our aerospace specialist. “Given the cost of production delays in this industry, these time savings translate to millions in avoided expenses.”

Automotive Development Acceleration

Automotive engineering involves complex assemblies and tight tolerances:

- Clay model digitization for immediate design development

- Tool and die validation before production commitment

- Assembly verification of complete systems

- Wear analysis for durability testing

A leading automotive manufacturer implementing our scanning protocols documented a 10-week reduction in overall development time for body components, primarily through the elimination of sequential measuring and modeling steps.

Medical Device Fast-Tracking

Medical engineering has specific regulatory and precision requirements:

- Human anatomy integration for ergonomic design

- Compliance documentation generation for regulatory submission

- Production verification for critical components

- Design history file creation with comprehensive digital records

“The regulatory documentation advantages alone save our medical device clients weeks of work,” explains our medical engineering consultant. “When comprehensive digital data automatically generates required verification records, the time savings are remarkable.”

Implementation Strategies for Maximum Time Savings

To achieve optimal time reduction, consider these implementation approaches.

Integrate Early in the Process

The earlier scanning enters your workflow, the greater the time savings:

- Establish digital foundation at project initiation

- Create baseline documentation before modifications

- Enable digital collaboration from day one

- Build comprehensive data repository as the project evolves

“The biggest implementation mistake we see is treating scanning as a verification tool only used near project completion,” notes our workflow specialist. “The greatest time savings come from building your entire project on a foundation of accurate digital data from the beginning.”

Optimize Resolution for Purpose

Not all scanning requires maximum resolution, and appropriate settings save time:

- High resolution for critical features and precision components

- Medium resolution for general engineering applications

- Low resolution for large-scale context and spatial relationships

- Mixed resolution targeting detail only where needed

Our product design team has developed resolution optimization protocols that reduce data processing time by 40-60% while maintaining necessary accuracy for specific applications.

Create Standardized Workflows

Consistent processes maximize time savings through predictability:

- Standardized scanning protocols for common scenarios

- Template-based processing for routine applications

- Consistent file naming and organization

- Automated report generation for standard analyses

The IEEE Computer Society confirms that organizations with standardized 3D scanning workflows achieve 30-45% greater time savings than those using ad-hoc implementations.

Real-World Time Savings: Case Studies

Case Study 1: Oil & Gas Component Redesign

A manufacturer of specialized petroleum equipment needed to redesign legacy components with no existing CAD data.

Challenge: Create modern replacements for 30-year-old equipment with complex geometries and critical interface requirements. Traditional reverse engineering would require weeks of painstaking measurement.

Solution: Implementing a comprehensive 3D scanning workflow:

- Complete component scanning using structured light technology

- Automated feature recognition for standard elements

- Hybrid modeling combining scan data with new design features

- Digital interference checking before production

Result: The redesign process was completed in 9 days compared to the estimated 6 weeks using traditional methods. The first prototype achieved perfect fit with existing systems, eliminating the typical trial-and-error cycle. Total project time savings exceeded 80%, allowing the product to reach market months ahead of schedule.

Case Study 2: Architectural Engineering Retrofit

An engineering firm specialized in retrofitting modern systems into historic buildings.

Challenge: Install complex HVAC systems in a 19th-century structure with irregular geometry, no existing plans, and strict preservation requirements. Traditional manual measurement would be time-consuming and incomplete.

Solution: Using 3D laser scanning to:

- Create comprehensive digital documentation of the entire structure

- Enable virtual design reviews with preservation authorities

- Identify optimal routing with minimal structural impact

- Prefabricate components with confidence in spatial accuracy

Result: The engineering team reduced on-site measurement time from an estimated 3 weeks to just 4 days. The comprehensive digital model allowed parallel work by multiple engineering disciplines, compressing the design phase by 65%. Prefabrication accuracy eliminated nearly all field modifications, reducing installation time by 70% compared to typical projects.

Case Study 3: Medical Device Compliance Acceleration

A medical device manufacturer needed to document compliance for an existing product line under new regulatory requirements.

Challenge: Create comprehensive dimensional documentation for complex devices already in production, with verification against original design intent. The manual measurement approach would require months of CMM programming and measurement.

Solution: Implementing a scanning-based validation protocol:

- High-precision structured light scanning of production samples

- Automated comparison against original CAD models

- Statistical analysis of production variation

- Comprehensive digital documentation package

Result: The compliance documentation process was completed in 3 weeks instead of the estimated 4 months using traditional methods. The comprehensive nature of the scan data eliminated regulatory questions about sampling adequacy, accelerating approval by an additional 6 weeks. The validated digital models also enabled rapid design modifications for future product improvements.

Overcoming Common Implementation Challenges

While the time savings of 3D scanning are substantial, several challenges can limit these benefits if not properly addressed.

Data Management Strategies

The comprehensive nature of scan data creates data management challenges:

- Implement tiered storage solutions appropriate to data lifecycle

- Establish clear file naming conventions and organization

- Create appropriate resolution versions for different uses

- Utilize cloud-based collaboration for distributed teams

“Poor data management can erase 30-40% of potential time savings,” warns our IT specialist. “A structured approach to organizing, sharing, and preserving scan data is essential to maintain efficiency advantages.”

Integration with Existing Systems

Maximizing time savings requires smooth data flow between systems:

- Validate format compatibility with CAD and analysis software

- Create streamlined conversion protocols where necessary

- Implement appropriate level of detail for each downstream application

- Establish version control procedures for evolving models

Our systems integration expert notes, “The interfaces between scanning and existing engineering systems often determine how much time is actually saved in practical application.”

Training and Skill Development

Human factors significantly impact realized time savings:

- Invest in proper initial training for scanning operators

- Develop application-specific best practices

- Create standard operating procedures for common scenarios

- Implement continuous improvement processes to refine workflows

According to the Manufacturing Extension Partnership, organizations that invest in comprehensive training realize approximately twice the time savings compared to those providing only basic operational instruction.

Future Directions: Emerging Time-Saving Technologies

The evolution of 3D scanning continues to accelerate, with several emerging trends promising even greater time efficiencies.

AI-Enhanced Processing

Artificial intelligence is dramatically reducing processing time requirements:

- Automatic feature recognition identifying common engineering elements

- Intelligent noise reduction improving data quality automatically

- Predictive completion of occluded or missing areas

- Smart deviation analysis focusing attention on critical variations

Research from the IEEE International Conference on Robotics and Automation indicates that AI-enhanced processing could reduce post-scan processing time by an additional 40-60% over the next three years.

Integration with Additive Manufacturing

The combination of 3D scanning with 3D printing creates powerful new workflows:

- Scan-to-print pipelines for rapid physical replication

- Topology optimization based on scan data analysis

- Hybrid manufacturing processes combining scanning and printing

- Digital inventory creation replacing physical spare parts storage

“The convergence of 3D scanning and additive manufacturing is creating entirely new possibilities for time compression,” observes our manufacturing specialist. “Components that once required weeks for fabrication can now move from concept to reality in days or even hours.”

Automated Mobile Scanning

The movement toward autonomous and mobile scanning promises further efficiencies:

- Robotic scanning systems for automated capture

- Drone-based large-scale scanning for infrastructure and large components

- Continuous monitoring applications tracking changes over time

- In-line production verification without human intervention

The Smithsonian Institution has pioneered automated capture systems that reduce human operation time by up to 90% while maintaining or improving data quality, pointing toward the future of ultra-efficient digitization.

Conclusion: Transforming Engineering Timelines Through Digital Capture

3D scanning has evolved from a specialized tool to an essential component of efficient engineering workflows. By dramatically compressing data acquisition time, enabling parallel processes, and creating comprehensive digital representations, this technology delivers time savings that transform project timelines while simultaneously improving quality and documentation.

Key takeaways for engineering decision-makers:

- Time compression of 50-80% is achievable for many engineering activities

- Parallel workflows multiply the efficiency of engineering teams

- Comprehensive digital data eliminates repeated measurements and verifications

- Integration throughout the process maximizes cumulative time savings

Whether you’re designing new products, retrofitting existing systems, validating production quality, or documenting for compliance, the strategic implementation of 3D scanning can deliver competitive advantages through dramatically improved time efficiency.

Ready to accelerate your engineering timelines? RDS offers consultation services to help you implement time-saving 3D scanning workflows for your specific engineering applications. Our team brings decades of combined experience optimizing processes across diverse industries.

What engineering bottlenecks could 3D scanning help you eliminate? Share your thoughts or questions in the comments below, or contact us directly to discuss your specific time-saving opportunities.