Transform Your Product Design Process with Cutting-Edge Scanning Technology

Did you know that implementing structured light 3D scanning can reduce product development cycles by up to 67%? In today’s hypercompetitive marketplace, where bringing products to market quickly can mean the difference between market leadership and obsolescence, structured light technology is revolutionizing how design teams operate.

If you’re struggling with long development cycles, accuracy issues in prototyping, or challenges capturing complex geometries, you’re likely missing a critical technological advantage that your competitors may already be leveraging.

Our product design specialists have implemented structured light scanning solutions for hundreds of clients across industries, and today we’re sharing the comprehensive insights that can transform your design process—whether you’re creating medical devices, consumer products, or industrial equipment.

What Is Structured Light 3D Scanning?

Before exploring applications, let’s establish a clear understanding of this powerful technology.

The Science Behind Structured Light Scanning

Structured light 3D scanning is an optical measurement technology that projects specific light patterns (typically grids or stripes) onto an object’s surface. By analyzing how these patterns deform when projected onto three-dimensional surfaces, the system calculates precise spatial coordinates for millions of points.

The basic process involves:

- Pattern Projection: A projector casts precisely calibrated light patterns onto the object

- Distortion Capture: Cameras record how the patterns deform across the object’s surface

- Triangulation Calculation: Software analyzes the distortion to calculate precise 3D coordinates

- Point Cloud Generation: Millions of measurement points create a comprehensive digital representation

- Mesh Creation: The point cloud converts to a polygonal mesh model

Unlike laser scanning which captures points sequentially, structured light captures entire surface areas simultaneously, making it significantly faster for many applications.

Key Components of a Structured Light System

A professional structured light scanning setup typically includes:

- Pattern projector: Projects calibrated light patterns (white light, blue light, or other wavelengths)

- One or more cameras: Capture the projected pattern distortions

- Calibration tools: Ensure accuracy and alignment of the system

- Processing software: Converts captured data into usable 3D models

- Mounting systems: Stabilize the components for precise capture

Advanced systems like those used by RDS often include automated turntables, multi-angle capture setups, and specialized software for specific applications like reverse engineering or quality inspection.

Why Structured Light Excels for Product Design Applications

Product designers face unique challenges that structured light technology addresses exceptionally well.

Speed: Accelerating Design Iterations

Perhaps the most significant advantage of structured light scanning for product design is the dramatic acceleration of development cycles:

- Rapid digitization: Capture complete product geometry in minutes rather than hours

- Quick iteration: Test, scan, modify, and repeat within a single day

- Immediate feedback: Evaluate physical prototypes digitally as soon as they’re produced

Research from the IEEE Engineering in Medicine and Biology Society found that structured light implementation reduced medical device prototype iteration cycles by 58% on average, allowing faster regulatory submission and market entry.

Accuracy: Capturing Critical Details

Product design often requires exceptional precision, particularly for:

- Mechanical interfaces: Where components must fit together perfectly

- Ergonomic surfaces: Where human interaction demands subtle contours

- Aesthetic details: Where visual design elements require exact reproduction

Modern structured light systems achieve accuracy to within 0.025mm—approximately half the width of a human hair. This level of precision ensures that what you design is exactly what you manufacture.

Completeness: Comprehensive Geometry Capture

Unlike traditional measurement methods which sample discrete points, structured light scanning captures complete surface geometry:

- Surface continuity: Every curve and contour is captured

- Hidden features: Multiple scan angles reveal details invisible from any single viewpoint

- Complex geometry: Organic shapes and intricate details are fully documented

The National Institute of Standards and Technology recognizes structured light scanning as one of the most comprehensive methods for capturing complete product geometry, essential for modern design workflows.

The Product Design Applications Transforming Industries

Structured light scanning has found diverse applications across the product design landscape.

Reverse Engineering Existing Products

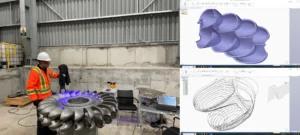

One of the most powerful applications is reverse engineering—creating editable CAD models from physical objects:

- Legacy part documentation: Recreate products no longer in production

- Competitive analysis: Understand competitor designs in detail

- Design evolution: Use existing products as starting points for new designs

- Replacement part creation: Develop compatible components for existing systems

Our reverse engineering specialists have found that structured light reduces reverse engineering time by approximately 60% compared to manual measurement techniques, while significantly improving accuracy.

Design Validation and Verification

For ensuring designs meet specifications before full production:

- Deviation analysis: Compare physical prototypes to CAD designs with color-mapped deviation reports

- GD&T verification: Confirm geometric dimensioning and tolerancing requirements

- Assembly fit checking: Virtually test component interfaces before physical assembly

- Design intent verification: Ensure the manufactured product matches designer vision

“Design validation with structured light scanning has reduced our rejection rate by 72%,” reports a medical device manufacturer who partnered with our product design team. “We identify and correct issues before they reach production.”

Ergonomic Design Optimization

For products with human interaction:

- Anthropometric data integration: Scan human subjects to inform design

- Comfort mapping: Analyze contact points between products and users

- Personalization: Create customized products based on individual scans

- Usability testing: Capture and analyze how users interact with prototypes

The American Society of Mechanical Engineers has published research showing that ergonomic designs developed with 3D scanning input demonstrate 35% higher user satisfaction scores compared to traditionally designed products.

Quality Control and Manufacturing Support

Beyond initial design, structured light scanning supports the entire product lifecycle:

- First article inspection: Verify first production runs against design specifications

- Production monitoring: Implement statistical process control with periodic scanning

- Tooling verification: Ensure manufacturing tools meet precise specifications

- Non-destructive testing: Identify potential defects without damaging products

Our clients using structured light for quality control report up to 88% reduction in customer returns due to quality issues, demonstrating the technology’s impact throughout the manufacturing process.

Implementing Structured Light Scanning in Your Design Workflow

Integrating this technology requires consideration of several key factors.

Choosing the Right System for Your Needs

Structured light systems vary significantly in capabilities and cost:

- Entry-level systems ($10,000-$25,000): Suitable for basic reverse engineering and simple product designs

- Mid-range solutions ($25,000-$80,000): Appropriate for most product design applications with good accuracy

- Professional systems ($80,000+): Necessary for high-precision medical, aerospace, or automotive applications

Key specifications to evaluate include:

- Accuracy: Typical range from 0.1mm to 0.01mm

- Resolution: Density of points the system can capture

- Field of view: Size of area captured in a single scan

- Software capabilities: Post-processing and analysis tools included

- Automation options: Turntables, robots, or other automated positioning

For design teams with intermittent needs, 3D scanning services offer access to professional equipment without capital investment.

Creating an Effective Scanning Environment

Environmental factors significantly impact scanning quality:

- Lighting control: Minimize ambient light interference with projected patterns

- Vibration isolation: Prevent movement during scanning

- Temperature stability: Avoid thermal expansion/contraction during scanning

- Surface preparation: Address reflective or transparent surfaces with temporary coatings

“Environmental control often separates professional results from amateur attempts,” notes our lead scanning technician. “We’ve created portable scanning environments that maintain optimal conditions even in challenging locations.”

Data Processing Workflow Optimization

Capturing data is just the beginning—processing that data efficiently is equally important:

- Scan alignment and merging: Combining multiple scans into a complete model

- Noise reduction and cleaning: Removing artifacts and unwanted data

- Mesh optimization: Creating efficient polygonal models

- CAD conversion: Transforming scan data into parametric models

- Deviation analysis: Comparing as-built to as-designed data

Professional workflows typically include specialized software like Geomagic Design X, Polyworks, or Rapidform for processing scan data into formats usable by CAD systems like SolidWorks, Inventor, or CATIA.

Real-World Case Studies: Structured Light in Action

Case Study 1: Consumer Electronics Ergonomic Redesign

A consumer electronics manufacturer needed to redesign a popular handheld device for improved ergonomics.

Challenge: The existing design caused user discomfort after extended use, but the complex curved surfaces were difficult to quantify.

Solution: We used structured light scanning to:

- Scan the original product

- Capture hand positions from 50 test subjects

- Create heat maps showing pressure points

- Develop an optimized design based on the data

- Validate the new ergonomic design through comparison scanning

Result: The redesigned product achieved a 63% improvement in comfort ratings and 28% increase in user session duration, leading to significantly higher customer satisfaction scores.

Case Study 2: Legacy Industrial Component Replacement

A manufacturing facility needed replacement parts for a critical system no longer supported by the original manufacturer.

Challenge: No original CAD data existed, and the complex cast components featured internal passages that couldn’t be measured conventionally.

Solution: Using our structured light scanning workflow:

- We performed multiple external scans of the components

- Used specialized techniques to capture internal geometry

- Created parametric CAD models with complete feature definition

- Optimized the designs to address previous failure points

- Produced replacement parts through 3D printing and traditional manufacturing

Result: The facility received replacement parts within two weeks instead of the estimated 3-6 months through traditional reverse engineering methods, preventing approximately $350,000 in downtime costs.

Case Study 3: Medical Device Development Process Transformation

A medical device startup needed to optimize their prototype iteration process to meet an aggressive development timeline.

Challenge: Traditional measurement and redesign methods were too slow to support their regulatory submission timeline.

Solution: We implemented a complete structured light scanning ecosystem:

- Integrated scanning directly into their design review process

- Established automated comparison protocols between iterations

- Created a digital library of all prototype versions with deviation data

- Developed custom reporting for regulatory documentation

Result: Development cycles shortened from 3 weeks to 5 days per iteration, allowing them to complete their design verification phase 4 months ahead of schedule and be first to market with their innovative device.

Advanced Techniques and Future Directions

The field of structured light scanning continues to evolve rapidly, with several emerging trends particularly relevant to product designers.

Multi-Sensor Integration

Next-generation systems combine structured light with complementary technologies:

- Structured light + CT scanning: External and internal geometry capture

- Structured light + thermal imaging: Form and function analysis

- Structured light + force measurement: Mechanical performance correlation

According to the IEEE Sensors Council, these hybrid approaches will define the next generation of product development tools.

AI-Enhanced Processing

Artificial intelligence is transforming how scan data is processed:

- Automatic feature recognition: Identifying functional elements without manual input

- Predictive modeling: Suggesting design improvements based on scan data

- Semantic segmentation: Automatically classifying different product components

- Self-improving accuracy: Systems that calibrate and optimize based on results

Early implementations of AI-enhanced scanning have shown 40-60% reductions in post-processing time while improving feature identification accuracy.

Integrated Design Ecosystems

The true power of structured light emerges when fully integrated into the design ecosystem:

- Scan-CAD-Manufacture pipelines: Seamless workflows from physical to digital and back

- Digital twin development: Creating virtual models that update with physical changes

- Augmented reality integration: Overlaying scan data and design intent in real-time

- Collaborative cloud-based platforms: Sharing and analyzing scan data across global teams

Research from the Smithsonian Institution’s Digitization Program demonstrates that integrated 3D data ecosystems improve team collaboration and decision-making throughout the design process.

Conclusion: Structured Light as a Competitive Advantage

Structured light 3D scanning has evolved from a specialized tool to an essential component of competitive product design. By dramatically accelerating development cycles, improving accuracy, and enabling comprehensive analysis, this technology provides a significant advantage in today’s fast-paced market.

Key takeaways for product design professionals:

- Speed advantages translate directly to faster time-to-market

- Accuracy improvements reduce costly design errors and manufacturing issues

- Comprehensive data capture enables better-informed design decisions

- Integration with existing workflows multiplies the value of current design tools

Whether you’re developing consumer products, medical devices, industrial equipment, or anything in between, structured light scanning offers transformative capabilities that can elevate your design process.

Ready to revolutionize your product design workflow? RDS offers comprehensive structured light scanning services, training, and implementation consultation. Our team brings decades of combined experience across diverse product categories and industries.

What product design challenges could structured light scanning help you overcome? Share your thoughts or questions in the comments below, or contact us directly to discuss your specific product development needs.