The Classic Car Restorer’s Biggest Challenge Ever held a broken camshaft from a 1967 Shelby GT500 and wondered how on earth you’ll find a replacement?…

Recreate every detail and transform physical parts into accurate digital models.

RDS – Reverse & Design Solutions

Main GT Road Karachi

Office Hour: 9am - 8pm / Mon - Fri

Phone Number

Recreate every detail and transform physical parts into accurate digital models.

Reverse engineering is the process of studying and recreating an existing part or product to understand its design and functionality. At RDS, we use advanced 3D scanning and CAD modeling tools to accurately capture every detail and rebuild digital models. This allows us to improve designs, reproduce parts, or create innovative solutions with precision and efficiency.

Our reverse engineering services are trusted by industries that value precision and innovation. From manufacturing and automotive to aerospace, product design, and engineering — we help businesses recreate parts and products with unmatched accuracy. Whether it’s for redesign, repair, or improvement, our technology makes the process faster, smarter, and more reliable.

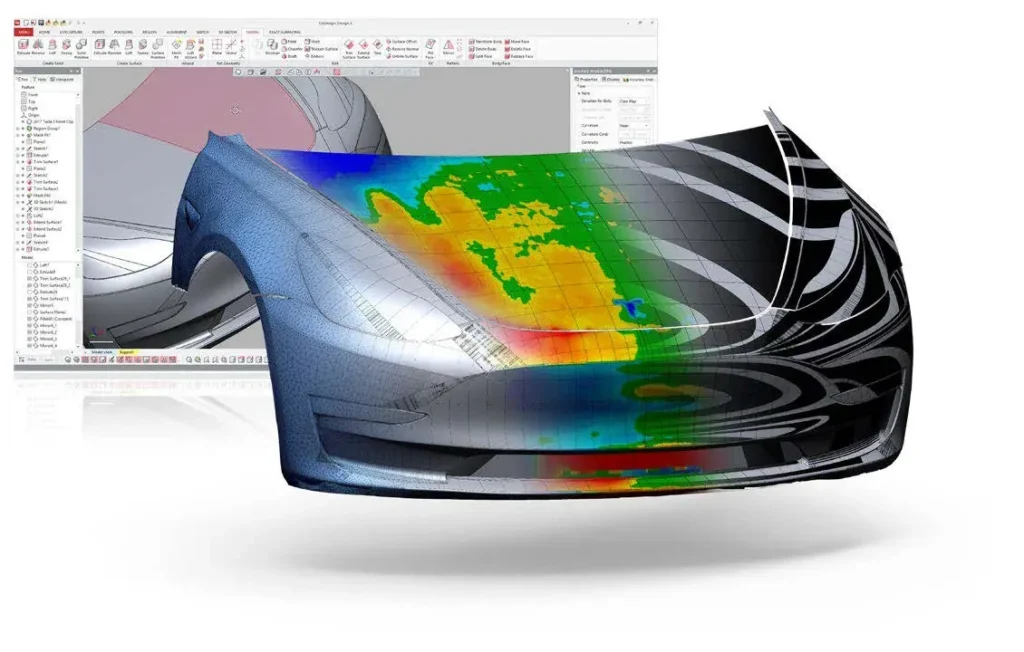

We proudly use Geomagic Design X, the industry-leading software for reverse engineering. It allows us to convert 3D scan data into accurate, fully editable CAD models with unmatched precision and efficiency. By using Design X, we ensure every project meets the highest standards of accuracy, compatibility, and design flexibility — giving our clients results they can truly rely on.

Our process guarantees quality, reliability, and customer satisfaction.

We start by analyzing your part, understanding its purpose, and defining the best reverse engineering approach.

Discover

Using high-precision scanners, we capture every detail of your part to create an accurate digital base.

Design

The scanned data is processed and converted into a detailed 3D CAD model ready for design or modification.

Deliver

We deliver accurate, editable CAD files in your preferred format for manufacturing, redesign, or analysis.

Support

We start by analyzing your part, understanding its purpose, and defining the best reverse engineering approach.

Using high-precision scanners, we capture every detail of your part to create an accurate digital base.

The scanned data is processed and converted into a detailed 3D CAD model ready for design or modification.

We deliver accurate, editable CAD files in your preferred format for manufacturing, redesign, or analysis.

We provide advanced reverse engineering solutions that turn physical parts into precise digital models. Using high-quality 3D scanning and CAD tools, we accurately capture every shape and detail — from small components to large industrial assemblies. Our skilled team ensures that every model we create is reliable, editable, and ready for design improvement, manufacturing, or analysis.

We’re here to help you recreate parts and products with accuracy and confidence. Whether you need digital models for redesign, repair, or manufacturing, our team ensures precision, reliability, and fast turnaround. Connect with us today — let’s transform your physical components into high-quality CAD models ready for your next project.

We use the latest 3D scanning and CAD software to recreate parts with precision and efficiency.

Our engineers bring deep expertise to every project, ensuring accurate and editable CAD models.

We deliver dependable, high-quality digital files that meet your design, repair, or manufacturing needs.

We deliver precise, reliable, and efficient reverse engineering services using advanced 3D technology and expert CAD modeling.

Reviewed By

4.8

From 500 Satisfied Clients

Provide Feedback on Trim & Prim

RDS did an amazing job with our 3D scanning project! The results were incredibly accurate, and communication was smooth throughout. The team explained everything clearly and delivered right on time. Really impressed with their professionalism and friendly attitude.

Get answers to your questions here!

We use advanced 3D scanners and CAD tools to capture every detail of a part, then convert it into a precise digital model.

Manufacturing, automotive, aerospace, product design, and industrial repair commonly use our reverse engineering services.

Yes! We can scan damaged or worn parts and digitally restore them to their original form with full accuracy.

We deliver files in formats like STEP, IGES, STL, or native CAD formats as per your project needs.

The duration depends on the part’s complexity and size, but most projects are completed within a few days.

Yes, our team specializes in both small and large-scale parts, including industrial machinery and assemblies.

Absolutely. We can modify or improve existing designs to enhance performance, fit, or manufacturability.

Our 3D scanning and modeling process delivers accuracy within microns, ensuring every detail is captured precisely.

Explore insights, updates, and trends shaping the future of automation.

The Classic Car Restorer’s Biggest Challenge Ever held a broken camshaft from a 1967 Shelby GT500 and wondered how on earth you’ll find a replacement?…

Tomorrow’s Products Are Being Designed Today: The Evolving Landscape of Industrial Design Did you know that 83% of executives identify design as a critical competitive…

Starting Your 3D Scanning Journey: The First Critical Decision Did you know that 68% of beginners who choose the wrong 3D scanning technology abandon their…